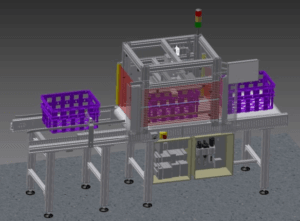

Traditionally, TestWorks Group has developed and supplied custom solutions for testing electronic, electrical and electromechanical units. However, we were commissioned to develop and build an automated solution to inspect and test a plastic milk crate as part of its production process. The crates are inspected and tested on a batch basis, so after exiting the moulding process and then cooling for a period of two hours, the crate is fed into the system. Initially the crate is automatically weighed to ensure that the correct quantity of plastic has been used and that the crate isn’t over- or undermoulded. The dimensions of the crate are then checked using laser scanners, followed by the application of a weight to the crate, which ensures that the level of deflection under load is within required parameters. The system is fully controlled using National Instruments LabVIEW software.

TestWorks Group has full electronic, mechanical and software design and build capabilities in-house, allowing us to provide a range of professional, cost-effective automated solutions. With the addition of full product design plus cable and box-build assembly this year through strategic acquisitions, we are more capable than ever of taking on such projects.