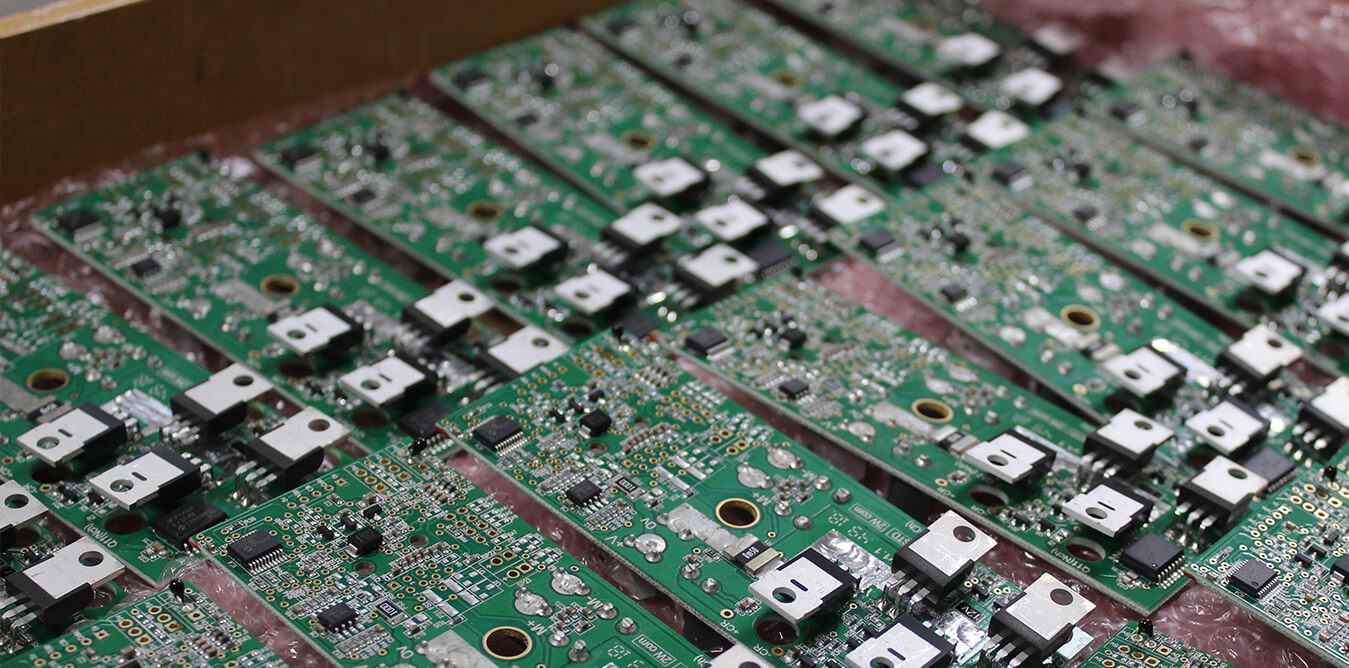

TestWorks Group electronics experts are able to offer a full range of complimentary Printed Circuit Board and Module Test Services, plus Production Support.

PCB, Module and Sub-Assembly Test and Repair Services

With a flying probe system on-site, dedicated solely to contract testing, TestWorks Group is perfectly positioned to offer a range of test services for small-to-medium volume PCB testing.

Whether used as an incremental service to complement your existing facilities during peak loads or as an integral part of your product manufacturing plan, TestWorks Group can offer a reliable low cost solution for all of your PCB testing and repair requirements.

Primarily aimed at prototypes, first off batches and smaller production runs, our quick turnaround PCB testing service allows your business to avoid wasting design engineers’ valuable time testing and repairing basic assembly errors. The flying probe technique allows a test program to be generated in a short period of time and, as no fixture is required, testing for short circuits, component values and general manufacturing defects can commence immediately.

We also have Automated Optical Inspection (AOI) and X-Ray systems available for contract test, and can therefore offer the most suitable solution for any given requirement.

For customers not yet ready to go ahead with automated functional test solutions, TestWorks can also provide a test service for functionally testing PCBs, Modules and Sub-assemblies, based on customer-supplied equipment or sourced by ourselves.

PCB Test & Repair Services

- Board test services

(flying probe, AOI, X-Ray) - Ideal for low-to-medium volume test requirements

- Electronic/electromechanical functional test services

- Using customer supplied and/or TestWorks Group’s own test equipment

On-site & Off-site Test Services

With an experienced and flexible electronics engineering team, TestWorks Group is able to provide your business with support at your own sites or at one of our facilities – whether for a single day or for longer contract periods, we are able to cater for all your test requirements.

Fixture Maintenance contracts

In order to get the most out of a test fixture it is important to understand the need for on-going maintenance. Typically, most test fixtures will have moving and mechanical parts, all of which are potentially prone to wear over time. TestWorks Group offers the option of an on-going maintenance support package for all TestWorks fixtures as well as many third party test fixtures. So, regardless of whether you have one test fixture or one hundred that you need maintained, TestWorks Group can provide the on-site service required on a contractual or ad-hoc basis – allowing your business to maximise the efficiency of its test fixtures and removing the risk of significant down time.

Design for test consultancy

With many years of experience in all aspects of electronic manufacturing test, TestWorks Group can provide the expertise your business requires in all aspects of design for test.

We can advise on how to ensure your product will be fully testable, and, for example, where additional test pads may need be added to your design where necessary, without degrading the electrical performance in any way.

Got a question? Need a quote? Get in touch.

Our team of experts are available to answer your questions and provide guidance on how we might help you tackle your project.